|

|

|

| The Niner Air 9 is our fast, light, geared-only alloy racing hardtail. This upgraded version integrates advanced features throughout:

NEW FRAME MATERIAL

For the updated Air 9, we have selected a newly available aluminum alloy from the 6000 series family. For those who are scandium loyalists, this may require a change in mindset, but the advantages of our selection are clear. For many years, the lightest alloy racing frames came with round tubes such as scandium. While a historically important material, scandium is not compliant with newly available hydroforming and production methods. When looking to produce advanced designs with a carefully tuned ride-feel, we have to look for better raw material options.

Our new alloy tubing produces a stronger Air 9 frame than the previous material. In testing, the new Air 9 is stiffer than previous round-tube models.

This new material allows us to double, triple or even quad butt the tubing where we see fit, giving us a light but compliant frame. Those of you riding the original Air 9 will be pleased with the great ride quality.

Our new alloy tubing loves to be shaped, giving us significant design freedom. We are now able to tune our alloy frame as carefully as we do our carbon frames, adding strength where needed and improving ride feel via tube-shaping methods. These methods complement our award-winning geometry to create an advanced alloy hardtail for racing applications. www.ninerbikes.com/hydroform

Our new alloy tubing is anodizing friendly. While not recommended for the previous material, the new Air 9 can be anodized, allowing folks to get a rugged and extra-light finish in a stealthy black, with low profile logos.

The new Air 9 will win more races. The net effect of a lighter, stronger and stiffer frame with better ride feel is a faster bike.

TAPERED HEADTUBE

The benefits of a tapered headtube aren’t just for riders of long travel bikes. XC racers and riders also see significant advantages, which is why we have incorporated the technology into the new Air 9.

By allowing for the use of the newest generation of tapered steerer suspension forks, we create the stiffest front end possible – leading to increased steering precision as you carve a corner and descend toward the finish line.

The change in headtube standards also allows us to incorporate an integrated headset – giving you the same stack height as our original Air 9, but with a significant increase in torsional stiffness.

|

|

|

The Air 9 features the award winning Niner hardtail geometry you know and love, with technology updates throughout.

|

|

|

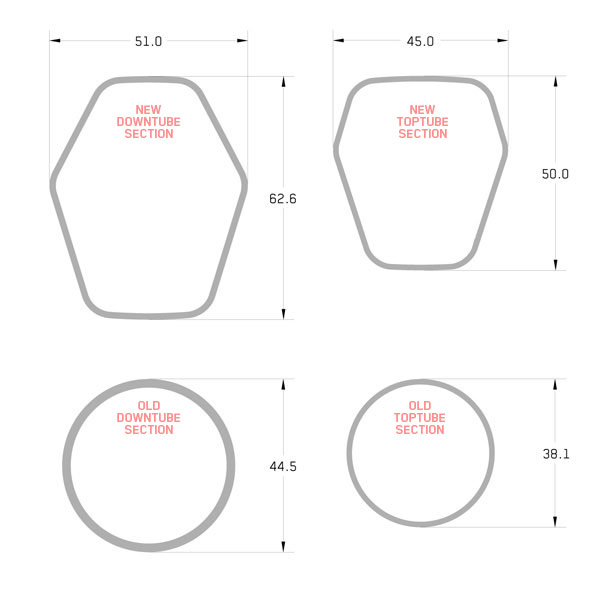

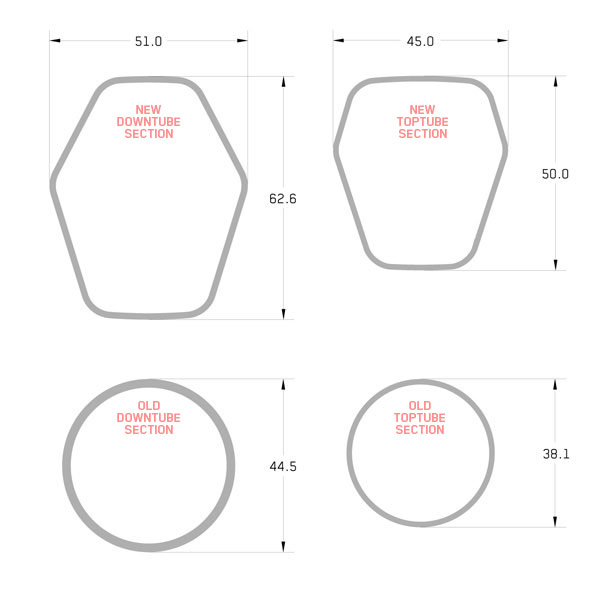

HYDROFORMED TUBING THROUGHOUT

Riders will notice significant changes to the look of the new Air 9, due to hydroformed tubing throughout the design. However the effect of this upgrade goes much further than appearance. Hydroforming allows us to shape the tubes and optimize strength and stiffness in key areas, giving us the ability to create beautifully tuned frames with the precise ride characteristics we seek for every application. In testing, this frame puts up stiffness numbers much higher than the original, with no weight penalty. We utilize hydroforming in the toptube, downtube, headtube, chainstays and seatstays. (For animation and more details see here)

Because of the larger welding area created by the new tapered headtube, we are able to include a new, massive, hydroformed downtube as well as a significantly larger diameter toptube, contributing to a much stronger frame.

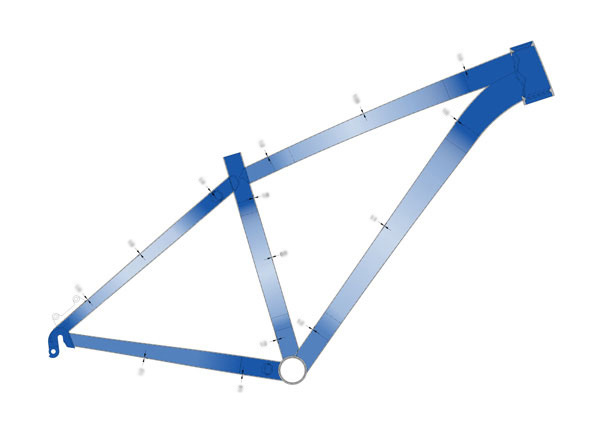

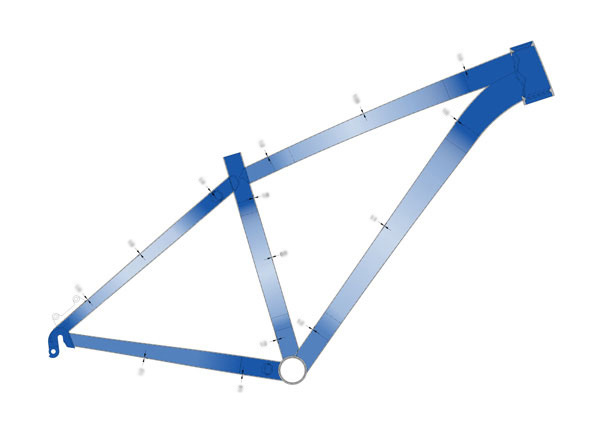

The shape of a tube is as important now as the material it is made from. Shaping has a huge effect on the way stress is distributed across and around a tube. Controlling the stress distribution enables us to use less material while maintaining, or even increasing, the frame strength.

Shaped tubing is found in many frames. It is important to be aware that how a tube is shaped can change the quality of the results. The least expensive method for shaping a tube is via mechanical forming. In this process, tube shapes are achieved by manipulating a straight gauge tube using mandrils, dies and, tube bending equipment. This approach has limits, particularly when it comes to tube bends and tube butting (wall thickness).To contrast, Niner uses a multi-stage hydroforming process – a straight gauge tube is butted and mechanically formed in preparation for the hydroforming process. Once the initial tube geometry is achieved, the tube is fully enclosed in a die, then pressurized with hydraulic fluid. This causes the aluminum to expand, obtaining the shape of the die. This process allows better control of wall thickness and more flexibility in cross sectional shaping over mechanical forming.

Chainstays, seat tube and seatstays also benefit from hydroforming, via controlled wall thicknesses for increased butting profiles . This translates to a rear triangle that is tuned for stiffness, strength and vertical compliance – in other words, ideal ride feel.

PRESS FIT 30 BB

The new Air 9 now uses the PRESS FIT 30 standard, allowing for further weight reduction. Shimano-style cranksets are compatible, via PF30 adaptors.

REAL WORLD WEIGHT SAVINGS

Finally, the question everyone asks – is it lighter than the old version? Yes. The frames are about 70g lighter than the original, with even more weight savings when considering the new component options:

OLD AIR 9 + EXTERNAL HEADSET + GXP BB = 1773g

NEW AIR 9 + INTEGRATED HEADSET + PF30 BB = 1661g

DIFFERENCE = 112g

Sample frame weights – size medium, new frame weighed in Anodized finish

|

|

|

Tubing cross sections demonstrate the power of hydroforming friendly materials.

We have achieved significant improvements in stiffness and strength, while reducing weight.

|

|

|

|

The new Air 9 joins the Niner flagship bikes in both aesthetics and technology.

|

|

|

|

|

This sketch shows both butting profiles and areas in need of varying wall thicknesses.

|

|

| AIR 9 FEATURES:

· THE AWARD-WINNING AIR 9 GETS A TECHNOLOGY UPDATE

· LIGHTER STIFFER ALLOY RACER FROM NINER BIKES

· CUSTOM HYDROFORMED ALUMINUM ALLOY TUBING FOR A CAREFULLY TUNED RIDE FEEL

· TAPERED HEADTUBE FOR STEERING PRECISION, STIFFNESS

· NINER’S PROVEN HARDTAIL 29er GEOMETRY

· OPTIMIZED FOR 80 TO 100MM SUSPENSION FORKS

· EXCEPTIONAL TIRE AND HEEL CLEARANCE

· DISC BRAKE ONLY

· PRESS FIT 30 BOTTOM BRACKET FOR WEIGHT SAVINGS

· REPLACEABLE DERAILLEUR HANGER

· AVAILABLE IN 3 FINISH OPTIONS, INCLUDING A NEW ANODIZED CHOICE

AVAILABILITY:

The Air 9 is shipping next week to European distributors. Our US warehouse expects to ship a limited number of Air 9 frames to dealers in 3-4 weeks.

|

|

| THE NEW NINER E.M.D. 9

The E.M.D. 9 may be the least expensive frame in the Niner lineup but it benefits from the same design process and expectations that we require from every Niner frame. Newly redesigned to integrate custom hydroformed tubing and a tapered headtube, the E.M.D. 9 is a worthy brother to the new Air 9.

Upgrades include a new tapered headtube, hydroformed downtube and significantly larger diameter toptube, contributing to a much stronger frame.

These upgrades also allow for the use of tapered steerer suspension forks and zerostack internal headsets, for the stiffest front end possible (with the same stack height as our original E.M.D. 9 model – complete specs here).

The E.M.D. 9 still features a standard bottom bracket, making this a friendly frame option for riders upgrading from a pre-existing bike.

The E.M.D. 9 sees an update to looks as well, with the new aesthetics reflecting the flagship bikes in the Niner lineup, and now including a matte black option for those seeking a stealthy look.

Frame finish details remain top-notch on the E.M.D. 9 – stainless steel Niner headbadge, reamed and faced headtube and bottom bracket, chased BB threads and faced disc brake mount tabs. For complete info, click here, to order, see your Niner dealer.

|

| E.M.D. 9 FEATURES:

· THE AWARD-WINNING E.M.D. 9 GETS A TECHNOLOGY UPDATE

· GREAT NINER DESIGN DETAILS AND FINISHES IN A HYDROFORMED ALLOY HARDTAIL

· TAPERED HEADTUBE FOR STEERING PRECISION, STIFFNESS

· NINER’S PROVEN HARDTAIL 29er GEOMETRY

· OPTIMIZED FOR 80 TO 100MM SUSPENSION FORKS

· EXCEPTIONAL TIRE AND HEEL CLEARANCE

· DISC BRAKE ONLY

· STANDARD BOTTOM BRACKET

· REPLACEABLE DERAILLEUR HANGER

· AVAILABLE IN HOT TAMALE OR MATTE BLACK PAINT FINISHES

AVAILABILITY:

The E.M.D. 9 is shipping next week to world-wide distributors. Our US warehouse expects to ship a limited number of E.M.D. 9 frames to dealers in 3-4 weeks.

|

|

|

Hydroformed tubing brings a new level of stiffness and strength to the E.M.D. 9

|

|

|

|

All the Niner details with the advantages of great technology like the tapered headtube.

|

|

|

|

Image courtesy Mike B.

|

|

| By now, you have probably seen Jet 9 RDO bikes popping up at your local races and online. We have a lot of folks out there riding their bikes, but due to high demand, we also have a lot of folks waiting.

The good news is that we are sending frames out on a regular basis, to points around the globe. Based on current estimates, everyone with a frame on order today should have one within 16 weeks, most people, much sooner. We fully expect this time-frame to come down as our new production line picks up speed, but we are trying to give a conservative estimate.

We know that it is tough waiting, but we believe that you think it is worthwhile once you ride your new bike!

|

|

| We had the opportunity to meet with Mountain Bike Action’s Editor, Jimmy Mac, at Press Camp. While we were there, we spent some time sharing info about our R&D program and test lab:

“The importance of such a significant investment in testing cannot be overstated. It is an added value to every Niner rider that may take the rider five to eight years to fully appreciate. This lab proves just how serious Niner is about their business and their future.”

Mountain Bike Action

To read the rest of the article, click here.

|

|

|